INDUSTRIAL

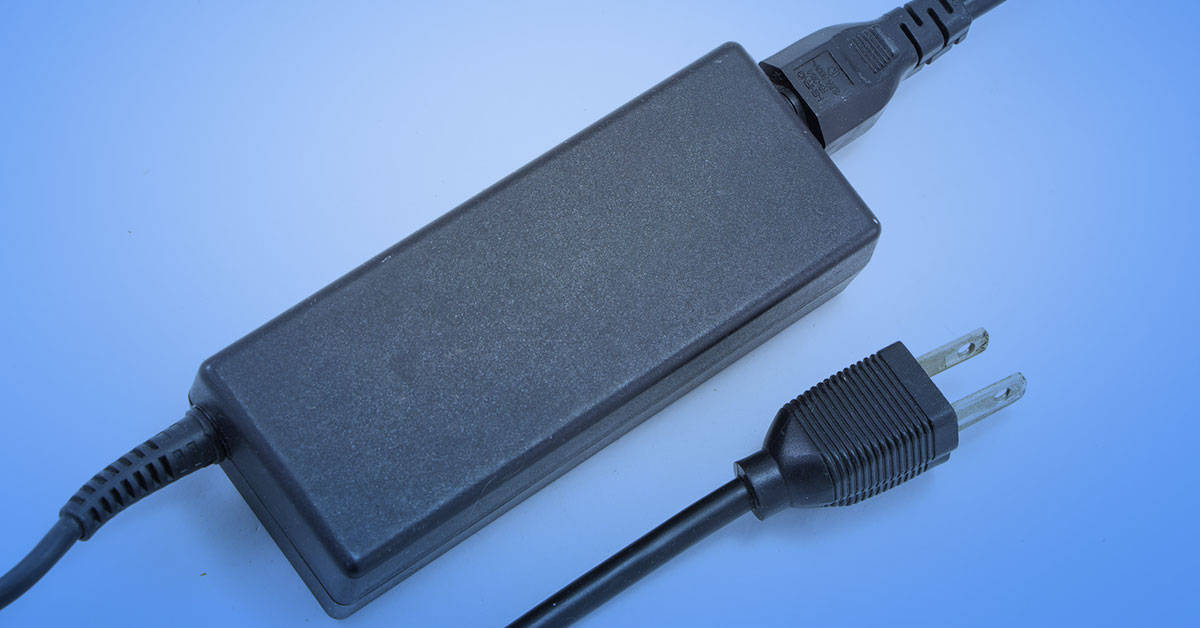

Smaller Size • Higher Efficiency • Lower System Cost

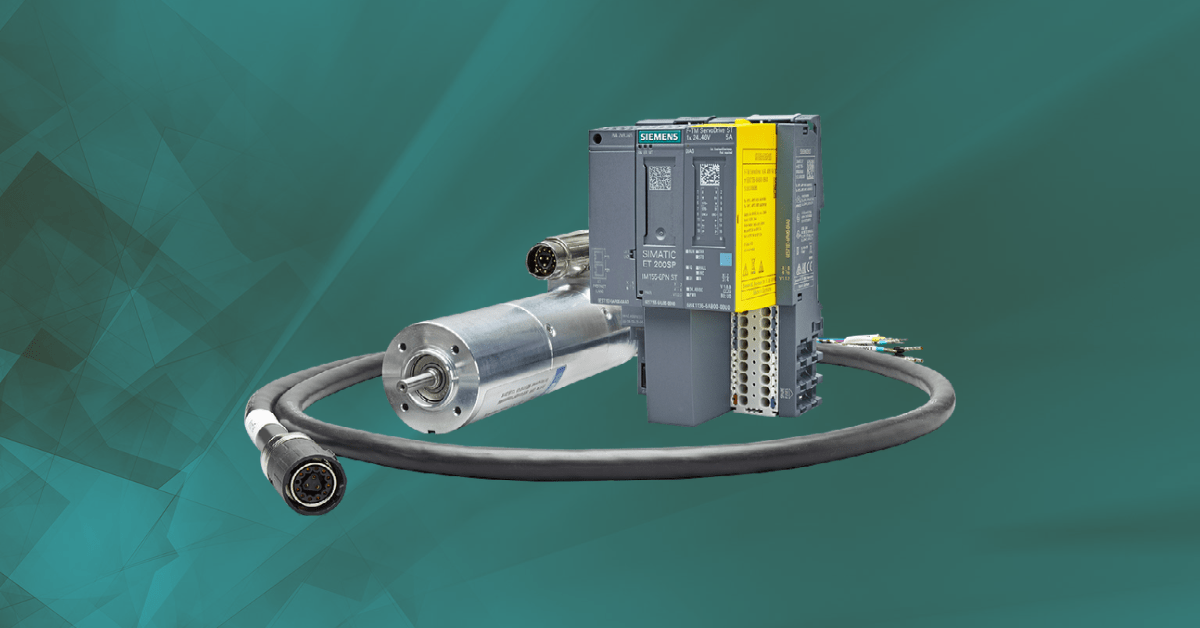

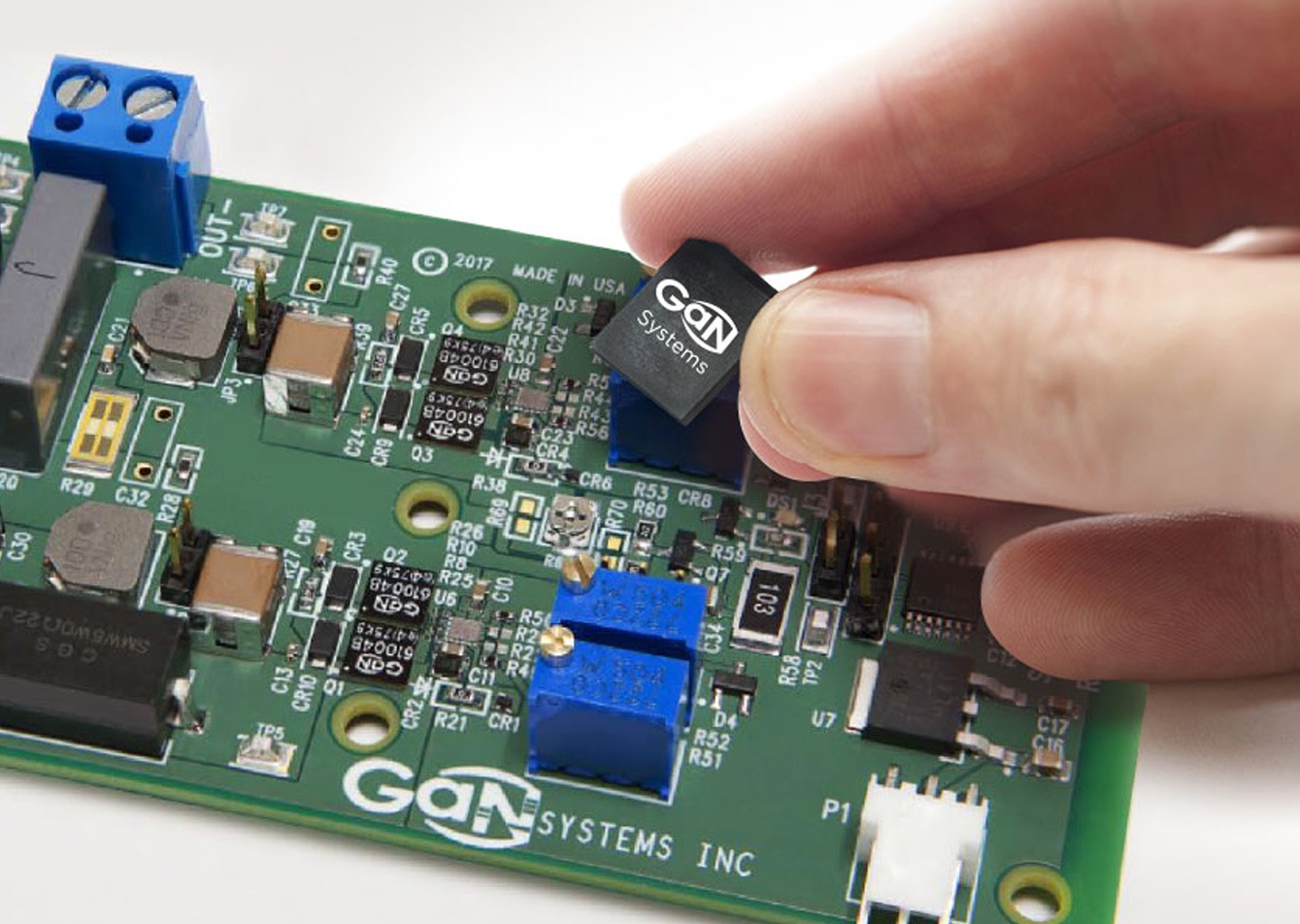

Industrial companies are experiencing escalating use and cost of electricity to power increasingly automated and power hungry systems. In order to keep costs down and the size of power systems small, increased energy efficiencies are needed. Using GaN Systems’ power semiconductors results in power supplies and motor drives that are more efficient and higher power density.

Global electricity consumed by motors and motion control

- Avionics & Aerospace

- Factory automation & robotics

- Industrial transport

- Lighting

- Medical devices

- Motor drives

- Avionics & Aerospace

- Factory automation & robotics

- Industrial transport

- Lighting

- Medical devices

- Motor drives