Fraunhofer ISE Develops Highly Compact, High-Frequency DC/DC Converter for Aviation Applications

This article was originally published in Semiconductor Today.

[Pictured above: Fraunhofer ISE’s resonant DC/DC converters, with a switching frequency of 2.5MHz, as a demonstrator for aeronautical applications. ©Fraunhofer ISE]

The efficiency of power electronic systems is not solely dependent on electrical efficiency but also on weight (e.g. in mobile systems). When the weight of relevant components and devices in airplanes, for example, is reduced, fuel savings can be achieved and correspondingly greenhouse-gas emissions decreased. New materials and components based on gallium nitride (GaN) can help to reduce weight and increase the efficiency. Power electronic switches can hence be operated at higher switching frequency, resulting in higher power density and lower material costs. Researchers at the Fraunhofer Institute for Solar Energy Systems ISE in Freiburg, Germany, together with partners, have investigated how these materials can be used to make power electronic systems in aviation applications more efficient.

In the project ‘GaN-resonant – Efficient, highly compact, high-frequency power electronics with GaN transistors’, consortium partners SUMIDA Components & Modules GmbH, Liebherr Elektronik GmbH and Fraunhofer ISE complement each other in the fields of inductive components, aviation technology and power electronics. The aim was to develop a resonant DC/DC converter using GaN transistors, with switching frequencies significantly above 1MHz and a nominal power of 3kW. The converter was designed especially for applications in aviation, where compatibility between the economic and ecological challenges plays a major role.

Compact design with high efficiency

To achieve the project’s ambitious target, the researchers and industry partners employed GaN power transistors together with innovative inductive components. Typical switching frequencies for these applications of currently up to 350kHz for resonant converters could hence be increased to 2.5MHz. “With these higher frequencies, a large part of the weight due to the passive components and the volume of the 3kW DC/DC converters could be appreciably reduced,” says Cornelius Armbruster, developing engineer in the team ‘Efficient and High Frequency Power Electronics’ at Fraunhofer ISE. By making the passive components smaller, less material (e.g. copper or ferrite) is required for manufacturing, saving scarce resources.

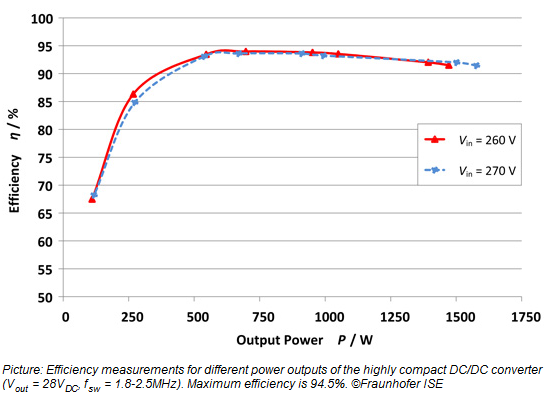

The beneficial dynamic behavior of GaN transistors allows high efficiency despite the high frequency. “The developed converter has a power/weight ratio of 3.9kW/kg and a total efficiency of over 90% for a wide operating range,” says Armbruster. “The converter reaches a comparatively high maximum efficiency of 94.5% at half its nominal power and a switching frequency of 2MHz,” he adds. However, at such high frequencies special care must be taken with the printed-circuit board (PCB) design, the measurement and control technology, and the electromagnetic compatibility. In consideration of these aspects, an eight-layer PCB was produced for the demonstrator and, in particular, control of the GaN transistors was developed and optimized.

Gallium nitride – a material with perspective

For years, Fraunhofer ISE has been undertaking R&D on high-efficiency, high-frequency power electronics for renewable energy systems and applications using the newest gallium nitride and silicon carbide (SiC) components. In the GaN-resonant project, the researchers and their project partners have developed a scenario for application in the aviation industry, designing the resonant voltage converter to meet the particular requirements of aviation electronics.

The results from the project can be transferred to other fields of application in the future, it is reckoned. One possible area of application is as a power supply for server farms, or for communication electronics in general. The amount of energy consumed worldwide to supply the existing communications infrastructure is immense, and all signs show that this will continue to rise. In this case, the design of the new compact, high-frequency DC/DC converter (saving on materials and reducing power losses) shows clear advantages, with not only higher efficiency but also lower cooling demand, says Fraunhofer ISE.

The GaN-resonant project was launched in 2013 and ran for a period of three years. It was funded with about €1.2m from the German Federal Ministry for Education and Research (BMBF) within the Hightech Strategy of the federal government under the IKT2020 Research & Development Program for Projects on Power Electronics (‘Leistungselektronik zur Energieeffizienzsteigerung’).