Article: GaN enables efficient, cost-effective 800V EV traction inverters

This article, written by Juncheng (Lucas) Lu and Peter Di Maso of GaN Systems, was published at EDN.com on May 22, 2020. Go here to read the piece in its entirety.

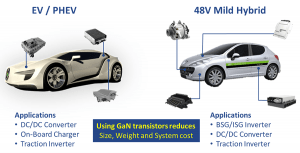

The number of electric vehicles (EVs) on the road has increased rapidly over the past few years and continues to accelerate. Industry analysts expect 56 million new EVs will be sold in 2040. The electricity consumption that accompanies this growth will rise to 1,800TWh representing 5% of global power, according to Bloomberg NEF’s Electric Vehicle Outlook, and that assumes an associated boost in electric vehicle efficiency, convenient charging infrastructure, and faster charging solutions. Smaller, lighter-weight electronics are key in creating changes for the EV industry and ecosystem.

There’s no better example of the need for greater efficiency than the main inverter in an EV. Within an electric drivetrain, the traction inverter converts DC current from the electric vehicle’s battery to AC current to be used by the motor to drive the vehicle’s propulsion system. Improving the traction inverter’s efficiency will enable:

- longer range, fewer charging cycles, and extended battery life with the same battery cost, or

- the use of smaller, lower-cost batteries to achieve the same range, both of which will help improve the viability of alternative vehicle technologies.

Read the rest of the piece at EDN here.